Used Course of Gear & Full Industrial Plants

페이지 정보

본문

Welcome to the biggest Online Complete Plant and Chemical Process Equipment Database. We purchase and sell quality, used course of tools, industrial chemical plants, refineries, and extra. LCEC has been a trusted useful resource for high quality chemical plant equipment for over 50 years. The LCEC Sales Crew is experienced and eager to help. View our latest state-of-the-art nitrogen plant for sale at Louisiana Chemical Gear Firm. Contact us for more info. Hydrocracker Reactor Part Unit 7500 converts a feed of Flashed Distillate, Waxy Distillate and Deasphalted Oil (DAO) in a Hydrogen rich environment into mainly Naphtha, Kerosene and Gas Oil merchandise that are despatched to Fractionation section U7600. The hydrogen plant was solely installed in 2007 and is based on Foster Wheeler technology. The plant produces 25,000 Nm³/hr of ninety nine.Ninety nine% pure H2. About Louisiana Chemical Gear Co., L.L.C. While a PID controller will react to an analog electrical sign that can fluctuate between four and 20 mA, a PLC will reply to numerous digital inputs. PLCs can handle 1000's of digital inputs and outputs. These digital inputs could embody whether a valve is open or shut or whether a motor is on or off. Notably giant-scale PLCs will double as analog controllers and supply PID management to processes as well. Very like a PID controller, a PLC will send an output signal to an actuator to adjust course of variables depending on how it is programmed.

Is your floor ending line well-designed? Materials selection for chemical process equipment is essential to the design and implementation of excessive-quality and cost-effective floor ending systems. The purpose of this seven-half collection is to discuss some fundamental data to help establish and plan for the advanced array of design and life cycle venture concerns for material choice for course of systems. Manufacturer of chemical process equipment together with corrosion-resistant thermoplastic valves, actuators, and single and double wall piping. Obtainable in a wide range of sizes, specs, options, and options. Supplies labored with embrace PP, PVDF, PE, HDPE, PVC, and CPVC. Suitable for bulk storage, blending and mixing, neutralization and industrial waste, and fume and ventilation applications. FOB delivery. Gives one-year restricted warranty. Distributor of chemical process equipment including bellow seal, management, safety, pressure regulating and reducing, and verify valves, strainers, and steam traps. Management valves are available with pneumatic and electric actuators.

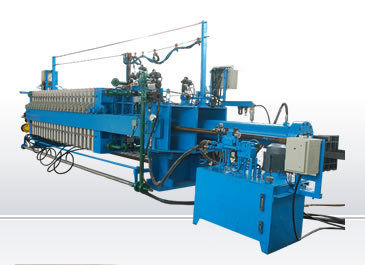

The feed pump is began so that it may well begin filling the void areas between the clamped filter plates. Throughout this fill step, the slurry feed rate could be very excessive and the feed pressure may be very low. To assist reduce cloth put on around the filter plate feed hole areas, the fill circulation charge is limited by controlling the pump pace. 6. Durable: Plate and frame filter presses are usually manufactured from materials equivalent to stainless steel or solid iron, that are durable and lengthy-lasting. 7. Reduced waste: Plate and frame filter presses can produce a dry filter cake, which reduces the quantity of waste generated through the filtration process. Eight. Steady operation: Plate and body filter presses will be operated in either a batch or steady mode, making them versatile for quite a lot of purposes. Overall, the plate and body filter press design presents a versatile, environment friendly, and cost-effective solution for a wide range of solid-liquid separation purposes. What's A RECESSED CHAMBER FILTER PRESS? A recessed chamber filter press is a type of filter press machine manufacturers press used for strong-liquid separation.

- 이전글Wondering How you can Make Your Seo Tool Rock? Read This! 25.01.09

- 다음글Mastering the Art of How to Pick a Winning Slot 25.01.09

댓글목록

등록된 댓글이 없습니다.